Blume serves industries that generate carbohydrate-, starch- or sugar-rich wastestreams or surplus materials. These materials become feedstocks that can be used to generate alcohol fuel (bioethanol) and in some cases valuable coproducts, that can be used in myriad ways, in product manufacturing (as a cleaning or extraction agent, solvent, or other processes), to offset current energy requirements, or for sale of products and coproducts to offtakers.

These systems are highly efficient and can generate rapid return-on-capital equipment investment (more).

Customer Profiles — Industries We Serve

Why do customers use Blume equipment to make this advanced biofuel? They often realize hidden revenue by harvesting the energy potential in waste streams, reduce waste disposal costs, and more.

Farmers

Commercial farmers have the opportunity to produce a finished product on their own land and even produce the fuel used by their vehicles and equipment. In the United States, specialty crops such as fodder beets and sweet sorghum may qualify for advanced biofuels tax credits.

Commercial farmers have the opportunity to produce a finished product on their own land and even produce the fuel used by their vehicles and equipment. In the United States, specialty crops such as fodder beets and sweet sorghum may qualify for advanced biofuels tax credits.

Consider an appropriate-scale Blume system to take advantage of these production incentives.

Farming in tropical or sub-tropical climates?

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Tropical Farming

Farming in tropical and subtropical climates can produce cost-effective alcohol fuel and coproducts from their waste or surplus materials, including these specialty crops:

What surplus or waste material does your operation currently generate? Consider an appropriate-scale Blume system to take advantage of the growing demand for bioethanol.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Bakeries

Bakeries often end up having waste carbohydrates (sugars and starch) that can be “upcycled” into alcohol fuel.

Bakeries often end up having waste carbohydrates (sugars and starch) that can be “upcycled” into alcohol fuel.

Sugary products are particularly rich raw materials for Blume Distillation systems, but carbohydrates such as grains make excellent feedstocks as well.

Even small bakeries can benefit from converting their waste into alcohol fuel, whether they use the alcohol themselves or sell it to an offtaker.

An investment in a Blume system can pay for itself in as little as 24 months.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Beverage Companies

Blume Distillation Systems offers beverage production facilities the latest in appropriate-scale technology for cost-effective conversion of sugar-rich surplus materials or processing waste into high-quality alcohol fuel and valuable co-products. We offer our customers a unique way to increase profitability through reducing disposal costs, lowering BOD in waste water, and generating revenue through fuel sales.

Blume Distillation Systems offers beverage production facilities the latest in appropriate-scale technology for cost-effective conversion of sugar-rich surplus materials or processing waste into high-quality alcohol fuel and valuable co-products. We offer our customers a unique way to increase profitability through reducing disposal costs, lowering BOD in waste water, and generating revenue through fuel sales.

For materials for which there is ordinarily no market, Blume systems may be your solution. An investment in a Blume system can pay for itself in as little as 24 months.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Food Processing

Blume systems offer food processing facilities the latest in appropriate-scale technology for cost-effective conversion of surplus or processing waste into high-quality alcohol fuel.

Blume systems offer food processing facilities the latest in appropriate-scale technology for cost-effective conversion of surplus or processing waste into high-quality alcohol fuel.

If your products contain sugar or starch, with surplus, culled, scrap or otherwise unused materials, it can be made into bioethanol plus potentially valuable secondary products.

We offer our customers a unique way to reduce disposal costs while providing a “green” and responsible source of incremental revenue. An investment in a Blume system can pay for itself in as little as 24 months.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Entrepreneurs / Independent Business Owners

Take advantage of the opportunity to convert surplus and waste into bioethanol at a substantial operating margin. Many companies that generate potentially valuable waste simply want to dispose of it. An independent business owner (IBO) can aggregate feedstocks and bring them to a central facility for processing into valuable fuel or higher quality purified ethanol.

Take advantage of the opportunity to convert surplus and waste into bioethanol at a substantial operating margin. Many companies that generate potentially valuable waste simply want to dispose of it. An independent business owner (IBO) can aggregate feedstocks and bring them to a central facility for processing into valuable fuel or higher quality purified ethanol.

With adequate and reliable feedstock supply, an investment in an appropriate-scale Blume system can pay for itself in as little as 24 months.

Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Waste haulers, aggregators

Instead of being simply the intermediary between the source of waste and its final disposal, waste haulers have to opportunity to increase profitability by processing selected loads into fuel. Blume’s feedstock flexibility provides a wide range of options.

Instead of being simply the intermediary between the source of waste and its final disposal, waste haulers have to opportunity to increase profitability by processing selected loads into fuel. Blume’s feedstock flexibility provides a wide range of options.

Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Municipalities / landfill operators

Landfill operators with the ability to segregate the carbohydrate-rich components of their waste streams have the opportunity to produce fuel with Blume equipment.

What pre-sorting techniques do you use?

Read also: cattail bioremediation and ethanol production case study.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Feedstock: Cattails Case Study

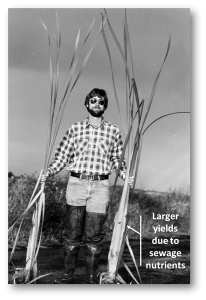

Cattails are an EPA-approved tertiary treatment option used in hundreds of facilities around the US. Cattails grow wild in nutrient enhanced waterways around the world. Engineered marshes can be harvested and processed into bioethanol.

Blume biological remediation solutions utilize cattails (an ideal fuel feedstock) to clean particulate discharge related to waste water treatment systems.

Cattails on the left are wild, while the larger yields on the right are due to nutrients in the bioremediation process.

Municipalities can make their own fleet fuel, or delegate to a third party, while meeting new stringent EPA guidelines.

Cattail benefits

- Proven – Widely accepted, often used bioremediation solution in US

- Regulatory compliance – meets EPA guidelines for estrogenic and phosphor discharge cleanup

- Yields valuable co-products including high-protein animal feed.

Pharmaceutical Companies

Drug manufacturers can both generate new ethanol from processed plant materials and recover ethanol used in manufacturing. Generate purified ethanol on site for a fraction of what it costs to purchase it.

Drug manufacturers can both generate new ethanol from processed plant materials and recover ethanol used in manufacturing. Generate purified ethanol on site for a fraction of what it costs to purchase it.

When product manufacturing involves botanicals or other materials containing carbohydrates, sugars, or starches, any surplus or otherwise unusable material can become feedstock for making alcohol. The system size for producing alcohol can be matched to available feedstock. Ethanol can be upgraded to food-grade or USP-grade for use in product formulas.

Got questions? Learn about Blume systems | Customer Benefits | Make a purchase inquiry

Nutraceuticals, Herbs & Dietary Supplements

Manufacturers of herbal medicines, nutraceuticals, or other natural products can use ethyl alcohol (bioethanol) in a variety of ways.

Manufacturers of herbal medicines, nutraceuticals, or other natural products can use ethyl alcohol (bioethanol) in a variety of ways.

When product manufacturing involves grains, plants or other materials containing carbohydrates, sugars, or starches, any surplus or otherwise unusable material can become feedstock for making alcohol fuel on site. System size can be matched to available feedstock volumes.

Ethanol can be upgraded and used in herbal tinctures, encapsulation or other products. Versatile alcohol is also an excellent clean-burning fuel and solvent for cleaning and related manufacturing and sanitizing processes.

Blume Distillation is committed to producing the highest quality food-grade and USP-grade alcohol for use in product formulas, as a solvent, or to offset energy requirements in operations. Why not generate purified ethanol on site for a fraction of what it costs to purchase it?

Your customers expect your operations to be safe, respectful to workers and the environment. Producing your own alcohol as a fuel or a processing agent may help comply with FDA & cGMP regulations that pertain to manufacturing, storage and distribution functions.

Learn about Blume systems | Customer benefits | Contact customer service for product information | Make a purchase inquiry